Industrial Robots

Omron TM Robots

The Delta solution can achieve up to 200 cycles per minute and can be synchronised with multiple conveyors to perform on-the-fly Pick & Place operations. There are 3 types of Delta robot arms available as Washdown, Delta and Mini Delta robot. The NJ controller offers a response time of 2 ms when controlling 8 Delta robots or 1 ms when controlling 4 robots.

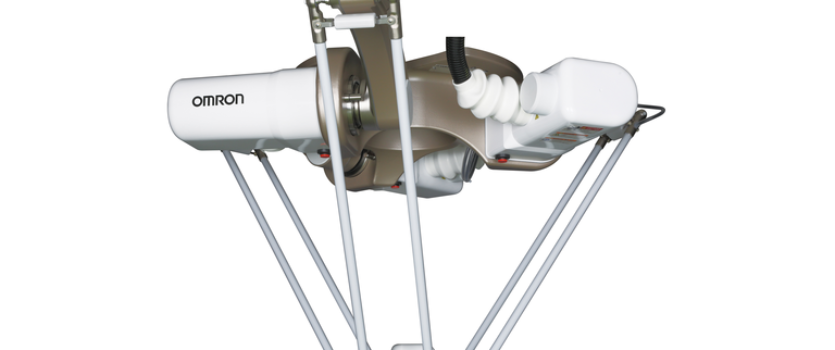

Delta Robot

ManEx cameras can be used to inspect printed data on products, such as barcodes, labels, and serial numbers. This can help to ensure that the data is accurate and readable, and it can also help to prevent counterfeiting.

The large amount of data in the built-in dictionary contains approximately 80 different fonts that are used on FA sites.Variations for worn characters, blurring, distortion, different backgrounds, and size changes have been included to enable stable and highly accurate reading with the built-in dictionary even for some variations in the characters.It is not necessary to set parameters to compensate for character contrast or positional offsetting.

HD-1500 AMR Robot

The 1,500 Kg payload Omron HD-1500 mobile robot handles the performance of simple transport, delivery, and routing operations so your employees can perform higher-value jobs. Designed to meet the industry’s latest requirements, our mobile robots interact with people to promote a collaborative, safe working environment.

Currently the HD-1500 is in product introduction stage and we will be adding product information and more documentation soon. Please stay tuned for updates and contact your Omron sales person to discuss your project

iX4 Parallel Robot

The iX4 Parallel robot excels at high-speed applications in packaging, manufacturing, assembly and material handling. It is the only parallel robot (or “delta robot”) in the world with our patented four-arm rotational platform, delivering maximum speed, maximum acceleration and exceptional performance across the entire work envelope. Ultra-compact controls and embedded amplifiers improve footprint

i4H SCARA Robot

The i4H is a next-generation SCARA robot that offers the performance and capability required to meet the demands of today’s manufacturing needs

With a fresh, high-performance industrial design, the i4H can achieve the production throughput to meet your manufacturing needs.

Key features:

- High payload up to 15kg

- High-speed cycle times

- Highly repeatable ±0.015mm positioning (XY)

- Space saving built-in controller

- Intuitive robot mounted LCD status display and RGB light ring

- Available in 650, 750, 850mm reach lengths and 210 or 410mm quill options

- Available in standard IP20, Cleanroom/ESD, IP65 and Foodgrade rated versions

Our Technology partners